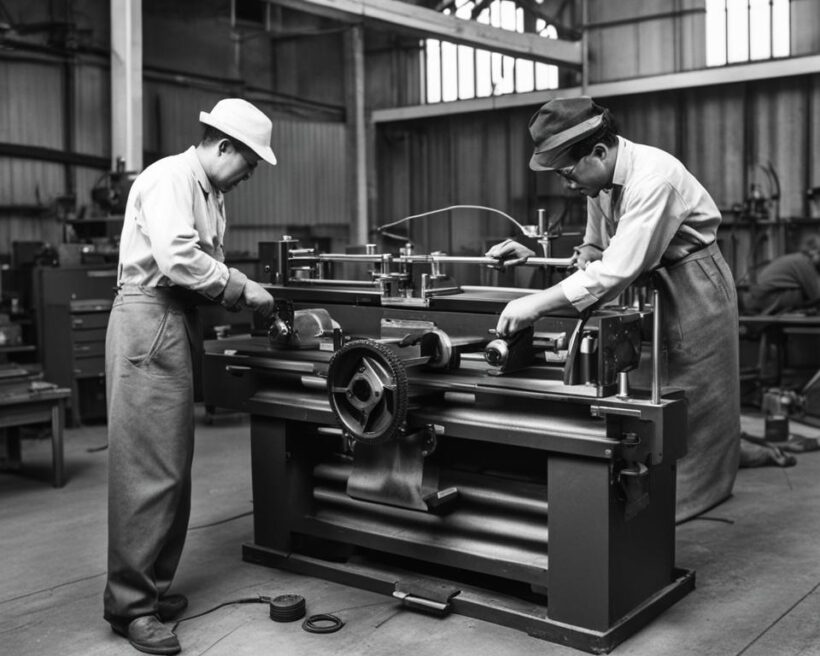

From securing gas lines to installing sprinkler systems, the art of pipe threading is an essential skill in my craftsmanship repertoire. Settling on the ideal Threading Machine is pivotal for ensuring stable and durable fittings, as each project demands precision matched with efficiency. In the throes of selecting between a manual pipe threading machine, an electric pipe threader, or perhaps a conduit pipe threading machine, my focus is always drawn towards machines that combine ease of use with technical prowess.

Whether my tasks involve ambitious renovations requiring the universal adaptability of a sophisticated threading tool, or more nuanced jobs that benefit from the simplicity in design of manual options, my choice is driven by not just the compatibility with my work but also by the promise of saving both energy and effort. Optimal machine weight for seamless mobility and an operational speed that hovers between the efficient 27-30 RPM range are non-negotiable parameters I weigh heavily. With an overview of the day’s labor ahead, the Threading Machine is more than an extension of my toolkit—it’s a testament to the quality and integrity of my work.

Understanding Your Threading Needs

My selection of the right threading machine is critical to the success of my projects. I’m currently on the lookout for a machine that can keep up with the demands of heavy remodeling, yet is suitable for my working space and budget. Grasping the type of work in hand is crucial; whether it’s employing a universal pipe threading machine for large-scale operations or a smaller conduit pipe threading machine for more precise tasks, each choice demands careful consideration.

Identifying the Scope of Work

When I evaluate the scope of my projects, it’s clear that larger jobs require robust solutions, such as a universal pipe threading machine. This type of equipment is designed to handle a variety of pipe sizes and materials, making it an indispensable tool for extensive renovations or the construction of new systems. On the other hand, specific and nuanced tasks can be accomplished with a manual pipe threading machine, which often provides the finesse needed for delicate work.

Considering Working Space and Finances

The availability of workspace can greatly influence my decision. In tighter quarters, an electric pipe threader or a conduit pipe threading machine may be more appropriate. These machines provide the precision I need without occupying an excessive amount of room, allowing me to maneuver and operate more freely. Financially, it’s also about finding the balance between upfront costs and long-term value; while a higher-priced machine may offer more features, a modestly priced model could also serve my needs without undue strain on my budget.

Choosing Between Manual and Electric Threading Machines

In my experience, manual pipe threading machines are a cost-effective solution when my workload doesn’t justify the expense of electric models. However, for repetitive tasks or when time is of the essence, an electric pipe threader offers a level of efficiency and ease of use that can be a game-changer. The convenience of these machines can significantly speed up my workflow, allowing me to accomplish more in less time.

Selecting the optimal threading machine is a blend of assessing my project demands, space considerations, and financial planning. Here’s how I differentiate between the types of machines available:

| Type of Machine | Best Used For | Space Consideration | Cost Effectiveness |

|---|---|---|---|

| Universal Pipe Threading Machine | Heavy-duty and diverse tasks | Requires more space | High upfront cost but long-term value |

| Manual Pipe Threading Machine | Specific jobs with finer detail | Low space requirement | More budget-friendly |

| Electric Pipe Threader | Efficient, time-sensitive projects | Medium space requirement | Higher cost but increases productivity |

| Conduit Pipe Threading Machine | Specialized threading in limited spaces | Compact design for small spaces | Varies depending on features and brand |

I have factored in all these elements to ensure the threading machine I choose will not only fulfill my current needs but also be a valuable addition to my tool arsenal for future projects.

Evaluating the Efficiency of Threading Machines

As I delve deeper into my selection process, I prioritize threading machine efficiency highly. It is imperative to choose a machine that not only saves energy and effort but also promotes a seamless work process within my working space. Notably, the physical footprint of a machine is a substantial factor, as a compact and lighter design translates to less clutter and more maneuverability.

Furthermore, the speed of the machine is another critical aspect. A rate that hovers in the ideal range of 27-30 RPM is optimal for achieving precise threads without sacrificing productivity. A semi-automatic machine, in particular, captures my attention due to its capability to streamline complex threading operations.

This blend of speed, weight, and automation ensures I am investing in a machine that’s not only energy-efficient but also one that maximizes my efforts day in and day out.

| Feature | Benefits |

|---|---|

| Semi-Automatic Function | Reduces manual labor, enhancing operational efficiency |

| Energy Saving | Decreases operating costs and supports sustainable practices |

| Lightweight Design | Facilitates handling and transportation, ideal for varied working environments |

| Optimal RPM | Ensures speed and precision in threading, improving project turnarounds |

Amid these considerations, a semi-automatic threading machine emerges as a standout choice, promising a precise balance between effort and effective results. This semi-automation grants me the luxury to focus on finer project details while the machine takes on the brunt of the physical work. It’s a win-win situation where the machine’s attributes directly contribute to a more streamlined and cost-effective work process.

Construction and Durability Features

When I consider the long-term value of a threading machine, I’m looking at how the construction and durability of the machine will stand up over time. The reality is, these aspects are what make a threading machine a smart investment rather than a temporary fix. The goal is to select a threading machine that withstands the demands of frequent use while remaining easy to transport and maintain.

Assessing Machine Weight and Portability

Machine weight is more than just a number—it speaks volumes about the threading machine’s portability and my ability to maneuver it across job sites. I search for a balance: a machine that’s light enough for easy transport, but with the durability to handle the rigors of pipe fabrication. Portability isn’t just a luxury; it’s a practical need that aligns with my dynamic working environments.

Quality of Components and Materials

Every threading machine comes with its own set of components, but not all are created equal. It’s the quality of these components—from the robust arm handle down to the gears—that ensures resilience and dependability. I scrutinize the materials, too, as they must resist wear and tear to reduce the frequency of maintenance. Components crafted from superior materials promise not just longevity, but also consistent performance.

Oiling Systems and Maintenance Ease

An efficient oiling system is central to the upkeep of any threading machine. It’s one of those features that directly influence maintenance ease and the performance of the equipment. A machine with a well-designed oiling system means less downtime and smoother operation, ensuring that the threading machine’s lifecycle is significantly extended.

Selecting a Trustworthy Threading Machine Seller

As I delve into my search for the ideal threading machine, one of the most crucial factors I consider is the reliability of the machine providers. A machine’s performance and longevity are as important as the support I receive from the seller. That’s why I prioritize choosing a trustworthy Threading Machine seller renowned for both quality products and excellent after-sale services.

Accurately gauging the reputability of machine sellers is not simply about anecdotal evidence but requires substantial customer feedback and authentic reviews. I look for consensus among past customers that point to a seller’s ability to deliver as promised, revealing a pattern of satisfaction that establishes a baseline for reliability.

Researching Seller Reputation and Reviews

In my pursuit, the reputation of a Threading Machine seller holds significant weight. A reliable seller is often distinguished by positive reviews and testimonials, which signal trust and quality. Scrutinizing what others have said about their experiences can offer me an insightful foretaste into what I might expect.

After-Sale Services and Support

I consider adequate after-sale support as a non-negotiable criterion when selecting a seller. This includes access to customer service for troubleshooting, proficient technical assistance, and a responsive contact center. These services render confidence that the seller is prepared to stand by their product.

Ensuring Legitimate Product Warranties

Finally, legitimate product warranties are the safety nets that protect my investment. A credible threading machine provider, like Solwet, typically extends a sound warranty that covers any unforeseen defects and repairs. This not only promises peace of mind but also attests to the seller’s confidence in their machinery’s quality and durability.

| Criteria | Importance | Notes |

|---|---|---|

| Reputation & Reviews | High | Positive feedback is a strong indicator of a seller’s reliability and product quality. |

| After-Sale Services | Critical | The availability of customer and technical support ensures continued satisfaction. |

| Product Warranties | Essential | A warranty reflects the seller’s commitment to their product’s performance and customer’s trust. |

In conclusion, selecting the right Threading Machine seller is tantamount to selecting the machine itself. In my role as both a consumer and a craftsperson, insisting on a seller that embodies these values is essential. The promise of robust after-sale services, rock-solid product warranties, and a proven track record cements my trust in a provider. With sellers like Solwet leading in trustworthiness and support, I am poised to make a purchase decision that is as informed as it is secure.

Threading Machine Accessories and Upkeep

My quest for precision in pipe threading has led me to incorporate a range of threading machine accessories into my toolkit. One standout accessory is the Milwaukee M18 pipe threader, a game-changer in cordless pipe threading. It offers convenience without compromising on power, which greatly enhances my threading efficiency.

Furthermore, Volkel threading tools are an integral part of my repertoire, respected for their comprehensive threading solutions. With these tools, executing thread pipe techniques becomes seamless due to their superior design and high-grade steel construction.

Maintenance practice is another crucial aspect that cannot be overlooked. I regularly use a pipe cutter for clean cuts before threading, ensuring my threads are clean and accurate. Additionally, proper lubrication with cutting oil is a must to keep the accessories in top condition. Here’s a breakdown of the accessories I rely on:

| Accessory | Function | Brand | Material Quality |

|---|---|---|---|

| Pipe Threader | Simplifies threading process | Milwaukee M18 | Cordless convenience |

| Threading Tools | Ensures thread precision | Volkel | High-grade steel |

| Pipe Cutter | Provides clean pipe cuts | Various | Durable and sharp |

To conclude, my threading work benefits immensely from the right selection of threading machine accessories and a disciplined approach to upkeep. With tools like the Milwaukee M18 threader and Volkel’s threading arsenal, combined with time-tested thread pipe techniques, I can approach each project with the confidence that comes from being well-equipped and well-prepared.

Conclusion

In the pursuit of precision and reliability in pipe threading, the journey to selecting the optimal Threading Machine encompasses a series of informed decisions. It is my responsibility to dissect my individual needs, understand the intricacies of efficiency, and scrutinize the longevity offered by each machine’s construction. My exploration into the market of threading equipment, driven by a pragmatic balance of financial wisdom and functional requirements, has led me to discover an array of robust options. With a focus on crafting a workspace that is both effective and sustainable, the guiding principles I’ve adhered to serve as a comprehensive Threading Machine buying guide for any professional in the field.

Recap of Key Threading Machine Features

When deliberating between an electric pipe threader and a manual pipe threading machine, my assessment weighs heavily on the specific applications of my work. The embracing of efficient threading machinery, capable of meeting the vigorous demands of my projects, has been paramount. Throughout this journey, recognition of the subtle attributes that define a quality threading apparatus—from semi-automatic operational ease to the critical oiling systems—has sharpened my eye for detail and preparedness for the tasks at hand.

Final Thoughts on Making an Informed Purchase

Standing at the crossroads of decision, the culmination of my efforts rests on the bedrock of due diligence. By grafting the insights gained, praising the merits of Solwet’s machinery reliability, and the flexibility imbued within VOLKEL threading tools, I am primed to make a selection that not only meets my immediate pipe threading necessities but also promises an enduring alliance with efficiency and craftsmanship. The echo of my comprehensive approach resonates with the assuredness of an investment that will continue to deliver, facilitating and transforming my professional endeavors into a legacy of well-threaded accomplishments.

FAQ

What is a Threading Machine used for?

A Threading Machine is used to create screw threads on pipes, making them suitable for assembly in systems like gas lines and sprinkler systems. This ensures a stable and secure fit for the piping.

How do I decide between a manual and an electric pipe threader?

Choosing between a manual pipe threading machine and an electric pipe threader depends on your scope of work, working space, and budget. Manual threaders are good for small, simple projects, while electric threaders are better for larger-scale or heavy remodeling projects that require power and efficiency.

What features should I look for in a pipe threading machine for efficient operations?

Key features for efficient operation include a machine that saves energy and effort, has a suitable weight for better portability, and ideally offers a semi-automatic mechanism. The operational speed of the threading machine should ideally be between 27-30 RPM.

How important is the construction and durability of a threading machine?

It’s crucial as it affects the machine’s longevity and reliability. High-quality arm handles, a robust oiling system for smooth operation, and durable material quality are all vital features that contribute to the threading machine’s overall construction and durability.

Why is it essential to buy from a trustworthy seller?

Purchasing from a reputable seller ensures that you are getting a quality threading machine with the assurance of after-sale services, technical support, and legitimate product warranties. This is critical for reliable operations and peace of mind.

Should accessories play a role in my decision when purchasing a threading machine?

Absolutely. The right accessories, such as the Milwaukee M18 pipe threader or Volkel threading tools, complement your threading machine and provide you with the versatility and ease needed for various threading tasks. They also have a crucial impact on the precision and efficiency of your work.

What is an electric pipe threader, and when should I consider it?

An electric pipe threader is a motorized device that automates the threading process, making it ideal for larger, repetitive projects where manual threading would be too time-consuming or labor-intensive.

What is a conduit pipe threading machine?

A conduit pipe threading machine is tailored for threading electrical conduits, which house and protect electrical wires. This type of machine is specialized for specific electrical applications where the standard sizes and threads for conduits need to be accurately produced.

How does the speed of the machine influence threading machine efficiency?

The speed of the machine, typically between 27-30 RPM, affects the threading process’s efficiency. A machine with the right speed ensures a balance between rapid operation and quality thread cuts, reducing the chances of pipe damage and rework.

What type of maintenance should be performed on a threading machine?

Regular maintenance like cleaning, oiling, and checking for wear and tear on components is essential. Using cutting oil during the threading process can also significantly extend the threading machine’s life by reducing the frictional forces at work.

How can I ensure that I’m buying a Threading Machine with adequate after-sale services?

Research the seller’s reputation and reviews online. Look for businesses that offer comprehensive customer support and technical assistance. Confirm the availability of legitimate product warranties before purchasing.

Can a threading machine be used for both plastic and metal pipes?

Yes, some threading machines are capable of handling both plastic and metal pipes, but it’s important to ensure that the machine and dies you are using are suitable for the material of the pipes you intend to thread.